Two of the most appreciated sports cars brand in the world just unveiled their new racing cars. Possibly the last ever to race all over the world in the FIA GT3 division without hybrid components. This endurance rivalry never extinguished, let’s get a closer look to Ferrari and Porsche latest weapons for customer teams.

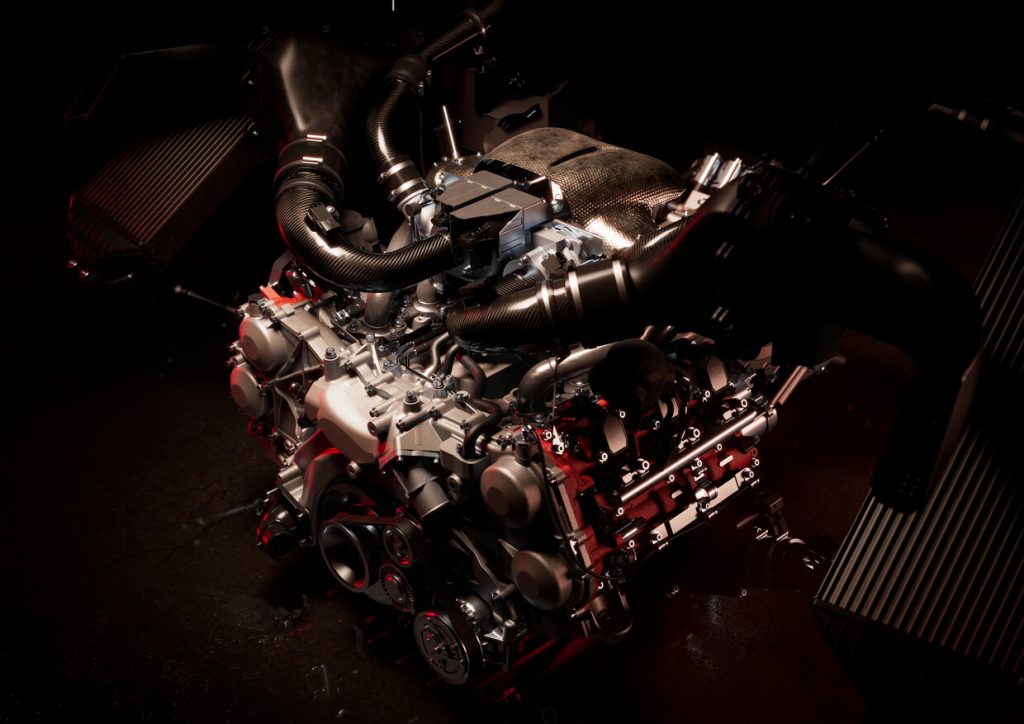

Engine and gearbox. The 296 GT3 marks the return to the track of a six-cylinder-engined Ferrari even though, in compliance with technical regulations, it doesn’t have the electric unit featured in the 296 GTB. A 120° configuration with equally-spaced firings was introduced for the 296 GT3’s V6 combustion engine. This is based on its road-going twin, as is the positioning of the turbos inside the vee. All this brings significant benefits in terms of compactness, lower centre of gravity and reduced mass, and also helps to achieve very high power levels. The engine, which has always been at the heart of Ferrari’s designs, is farther forward and lower down than in the road version, to the benefit of a lower centre of gravity and torsional rigidity, which is around 10% higher than in the 488 GT3.

The architecture is a winner in terms of firing order, integration of the intake manifolds and engine mounts on the intake sides of the cylinder heads: the engine is lighter and more compact having eliminated the external plenums and supports. Its internal fluid dynamics benefit from the reduction in volume, boosting intake efficiency.

Ferrari’s engineers worked with those of its partners to design and fine-tune all the engine’s internal fluid dynamics and the specific components adopted for the track version of the power unit. They aimed to provide uncompromising performance, reliability and driveability for both ‘Sprint’ and ‘Endurance’ races. For this type of competition, they did everything to limit consumption significantly without sacrificing performance, aiming for more flexible race strategies and reduced intervention times. For example, the alternator is attached to the gearbox to improve the unit’s compactness and rigidity and make it easier for technicians to access.

The gearbox of the 296 GT3 is new and specially developed for this car. The designers opted for a single-disc clutch unit with six gears, arranged transversely for better aerodynamics and weight distribution. Clutch actuation is now electronic and can be controlled from the steering wheel, rather than mechanical via the foot pedal, while the gear change is electrically actuated. The miniaturisation of the components and the use of premium materials made it possible to keep the weight of the Xtrac gearbox down, benefiting performance.

Exterior and aerodynamics. Ferrari’s future in GT racing is sinuous in form, enfolding the volumes of the 296 GTB, redefining them to meet the requirements of the track and performance thanks to the teamwork between Centro Stile, aerodynamicists and designers. This is why the car’s design, minus the aerodynamic devices or features specific to the racing version, has retained its connection to the production model. The design of the latter already refers back to vehicles such as the 250 LM of 1963, a perfect combination of simplicity and functionality.

The Ferrari engineers have been able to define an aerodynamic configuration within the homologation performance window by reducing ride height sensitivities with the aim of improving handling and driveability. This precise and detailed work on the shapes yielded a gain of 20% in downforce on the car over the previous generation. From this perspective, the 296 GT3 lives in symbiosis with the air around it, exploiting it to maximise grip and handling, benefiting gentlemen drivers and professionals alike. The challenge met by the designers was to limit the car’s sensitivity to the forces generated by aerodynamics, to provide an extraordinary balance for the benefit of driveability and driver confidence. The geometry of all the components, from the body to the wing appendages, was designed in detail under varying operating conditions and in mutual aerodynamic interaction to optimise performance and make it robust in different racing contexts, also when in the slipstream of other cars. From the front splitter to the rear extractor, which has a diffusor with a sophisticated three-dimensional design, the 296 GT3 stands out through a refined design that aims to achieve the lowest possible drag.

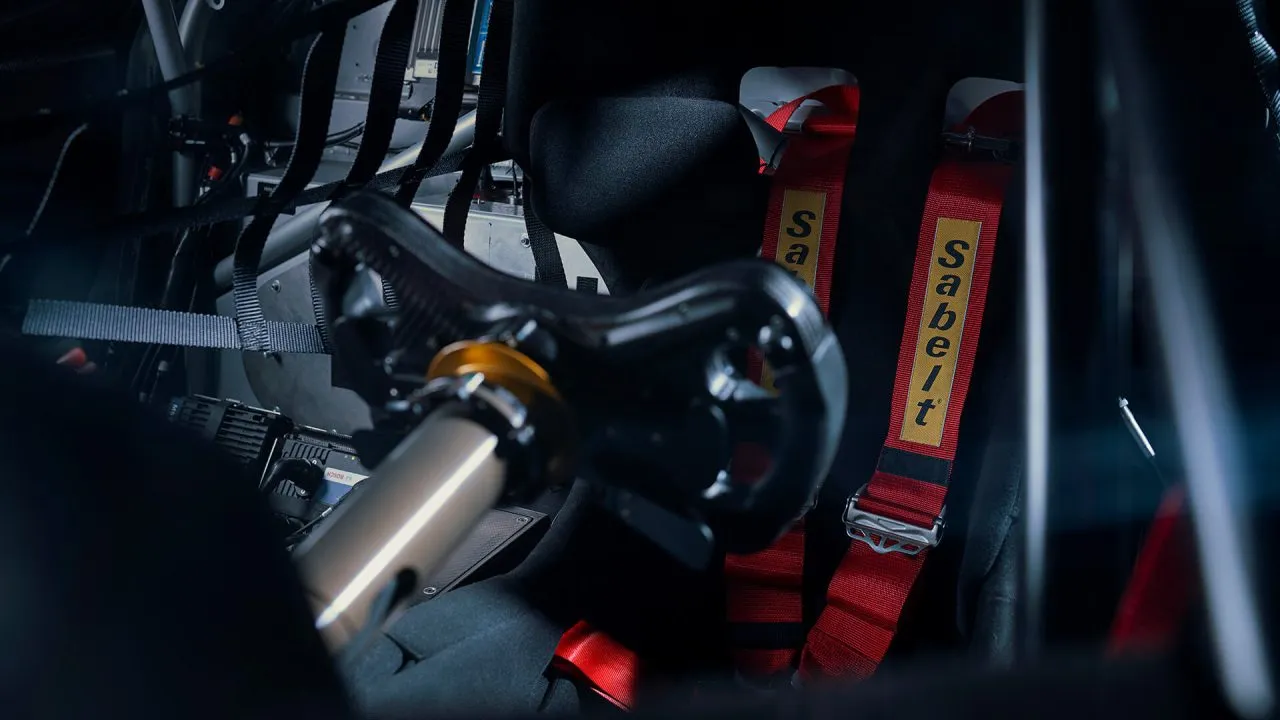

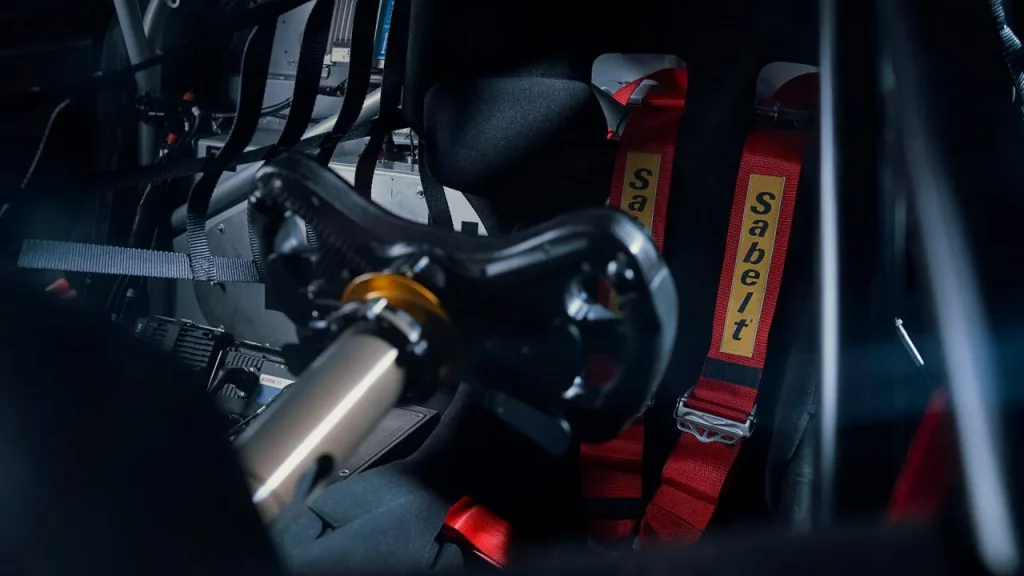

Cockpit. Intuitiveness, visibility and accessibility are critical to the development of the cabin design without neglecting essential aspects such as safety and comfort. In endurance racing, performance depends on these features, particularly for gentlemen drivers. The cabin was completely redesigned over the 488 GT3, in response to input from factory drivers and customers. The result is a cockpit that allows its occupant to quickly and effectively find the best driving position, with the main functions always within easy reach. Many controls and functions have moved to the new Formula 1 single seater-inspired steering wheel, while the position of the Sabelt seat provides optimal visibility, both day and night. It also adds a new level of comfort for drivers of different sizes and statures who can use the adjustable pedals and steering to find their best position in the car. The air conditioning system and airflow inside the cabin were designed to provide adequate ventilation in all conditions, helping the driver to concentrate during every stage of a race.

Chassis and vehicle dynamics. While the 296 GT3 chassis draws on the experience of the 488 GT3, it is entirely new and is made of aluminium. Besides being extremely easy and fun to drive, the 296 GT3 can exploit the grip potential offered by the tyres without compromising their integrity in just a few laps, benefiting performance and repeatability. The chassis’ extreme lightness, which in the 296 GT3 also allows better and more efficient ballast management, contributes to this. The safety structure has been carefully designed using the most sophisticated simulations and innovative technologies and research, especially in alloys and materials.

The 296 GT3 has a longer wheelbase than its road-going counterpart, within the regulatory limits, and a different suspension design to the 488 GT3, with dedicated kinematics and structures. The double wishbone arms in the front and rear suspensions are designed to offer maximum grip even at high speeds, limiting stress on the tyres as far as possible, to the benefit of tyre life, performance and reliability. The suspension, like the anti-roll bars, features the widest possible range of settings providing drivers with the best possible setup. The braking system was also revised and upgraded, with newly designed callipers and discs (now 400 mm at the front). Rotiform has developed an all-new, forged wheel homologated specifically for the 296 GT3. Encompassed in the partnership, the new Rotiform design will be the exclusive wheel offered for all factory Ferrari 296 GT3 professional level racecars.

In designing the 296 GT3, Ferrari’s engineers focused on speeding up track operations on the car during the race and pre-race. From this point of view, it is easier to modify the 296 GT3’s setup than the previous model due to more accessible mechanical and elastic components. Operations related to checks on the engine or major accessory systems were also significantly improved to cut intervention time on the car. However, the new Ferrari also differs significantly from its rivals in terms of replacing significant parts of the car. The front and rear portions can be switched in seconds due to a series of devices and solutions that ensure a quick return to the track after any damage affecting aerodynamics or performance.

Engine and gearbox. At the core of the new racing car is the near-standard engine based on the 992-generation 911 power plant. Like in the previous model, it is a water-cooled flat-six engine with four-valve technology and direct fuel injection. The main new development is the displacement: like the 911 RSR, the capacity of the new 911 GT3 R has increased by a good five per cent from 3,997 to 4,194 cc. This has boosted the engine’s peak output to around 565 hp. First and foremost, however, Porsche has optimised the torque and power curve across the entire rev range. Consequently, the new 4.2-litre six-cylinder is better suited to gentleman drivers.

The high-revving six-cylinder manages without turbocharging and sits in the classic rear position, thus enhancing traction and braking. However, it has been tilted forwards by 5.5 degrees, creating more leeway for the underbody diffuser. Auxiliary units such as the alternator and the air conditioning compressor were moved a good metre forward and further down into a space in front of the engine and gearbox, which has a positive effect on the weight balance of the 911 GT3 R. The sequential six-speed contest-mesh gearbox is derived from the current 911 GT3 Cup. Shift paddles control an electronic shift drum actuator that enables particularly rapid and precise gear changes.

Chassis and vehicle dynamics. The new 911 GT3 R’s suspension – many details of which have been modified – supports driveability, allows more precise steering, ensures less wear on the rear tyres and reduces the time spent on set-up changes. For this, numerous components and technical solutions were taken from the 911 RSR. At the front axle, a state-of-the-art double wishbone layout controls the wheels. The rear axle sports a multi-link design. The KW shock absorbers were further improved and offer five adjustment settings. Set-up modifications are done with so-called shims. These plates enable precision adjustments without the need for the time-consuming re-alignment of the suspension afterwards.

The optimised positioning of the central pivot points at the front axle frees up space for the aerodynamic “race underfloor” concept. Like in the 911 RSR, this elevated underbody allows for a clean flow of air to the rear diffuser and reduces the pitch sensitivity of the racing car – i.e. a high rake under braking. The rear wheels have moved a little further back, which extends the wheelbase from 2,459 to 2,507 millimetres. This also reduces the load on the rear tyres and improves the consistency of the tyres’ performance over longer stints.

In addition to the aluminium monobloc racing brake callipers, the brake discs on the new 911 GT3 R are now also supplied by the specialist company AP. The internally vented and slotted front steel discs measure 390 mm in diameter and are activated by six pistons. Fitted at the rear are four-piston callipers and discs measuring 370 mm. A sophisticated software application for the fifth-generation racing ABS reduces wear on the tyres and brakes. Porsche’s traction control system also received a further development.

GT3 R’s lightweight body with an intelligent aluminium-steel composite design draws on the production model, albeit with major modifications for use in the 911 GT3 R. Almost all body components are made of lightweight carbon, including the front and rear lids, doors, side panels, rear wing and roof. The wheel arches are made of aramid fibres.

In a vehicle like the new 911 GT3 R, functionality stands at the forefront. Nevertheless, Grant Larson from Style Porsche again succeeded in creating particularly stunning and harmonious shapes. They accentuate the heritage of the nine-eleven and blend it with sophisticated efficiency. Most notably, this is reflected in the aerodynamics. The key points: an elevated underbody at the fore of the front axle, for the first time in conjunction with a smooth undertray, and a rear diffuser. This combination improves downforce without a significant increase in drag. The rear wing now features a swan-neck mount. This ensures a clean airflow under the wing and thus improves the aerodynamic efficiency of the component.

Cockpit. In terms of safety, the new 911 GT3 R follows an uncompromising approach. The seat has moved closer to the centre of the car. This enabled Porsche to optimally adapt the more ergonomic seat position to the improved roll cage and the newly developed FIA side impact protection. Like in the forerunner, the steering wheel and pedals can be adjusted longitudinally to suit the driver. Porsche specialists took another close look at the six-point safety harness: the tongues now slide even faster into the clasp via special ramps – saving about a second during pit stops for driver changes. The steering wheel design also received further upgrades on the previous model. It incorporates elements that have proven themselves in the latest generation 911 GT3 Cup and 911 RSR race cars. The 10.3-inch display, for example, comes from the successful one-make cup racer, with the multi-switch concept adopted from the Le Mans class winner.

The high-performance LED headlights on the 911 GT3 R rely on so-called collimator technology, which Porsche developed for the new LMDh 963 prototype, among others. This device works like a magnifying glass, only in reverse. It illuminates a particularly large area of the racetrack and is a significant improvement on the predecessor model, which was previously regarded as the class leader.